The Centre for Flow Processing (CFP) is the dedicated research arm of CALGAVIN, uniting academic research and industrial expertise in fluid flow, heat and mass transfer. CFP is revolutionising industrial performance by solving process challenges and developing energy efficient technologies that meet the demands of tomorrow’s world.

Get in touchWhat is the centre for flow processing?

Partner with CFP and benefit from:

Fundamental research

Custom Solutions

Collaborative Innovation

Comprehensive Support

Fundamental Research

The Centre for Flow Processing serves as a focal point for integrating commercial application-specific research with university-led students. Through our strong partnerships with the UK and European universities – most notably, the University of Birmingham’s department of Chemical Engineering – CALGAVIN stands at the forefront of science-led technological advancements.

Get in touch

Custom Solutions

Partnering with industry to solve the most complex flow processing challenges.

- Delivering tailored, end-to-end solutions in heat and mass transfer - from concept and design to full implementation.

- Developing bespoke systems that balance innovation with practicality.

- Driving sustainability through cost-effective, energy-efficient technologies that create lasting value.

Collaborative Innovation

Bridging the gap between university phenomena and industrial needs, the Centre for Flow Processing serves as a focal point for integrating commercial application-specific research with university-led students. Through our strong partnerships with the UK and European universities – most notably, the University of Birmingham’s department of Chemical Engineering – CALGAVIN stands at the forefront of science-led technological advancements.

Get in touch

Comprehensive Support

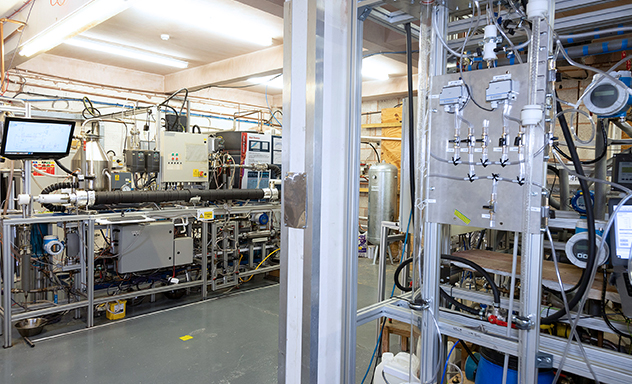

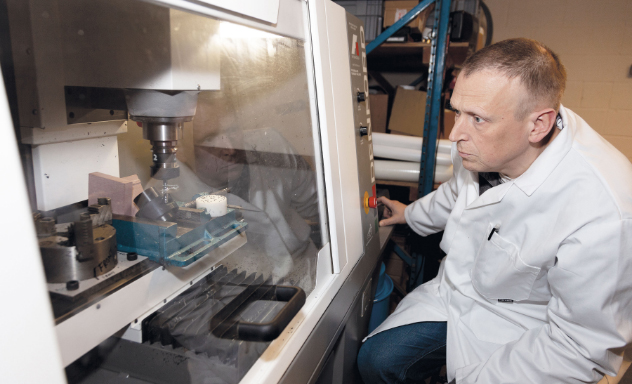

The Centre for Flow provides comprehensive support through a fully integrated, end-to-end service that covers every stage of a project’s lifecycle. From initial research and development, concept design, and prototyping, through to installation and on-site technical support, their team ensures seamless execution and reliable performance. This holistic approach not only accelerates innovation but also provides clients with confidence that their systems are optimised, sustainable, and backed by expert guidance at every step.

Get in touch

Case Study: Shifting Critical Heat Flux

To address the challenge of critical heat flux in fusion cooling channels, we partnered with the UK Atomic Energy Authority to study enhance heat transfer performance.

Leveraging expertise in heat transfer and fluid dynamics a specialised test facility was designed and built to replicate boiling liquid flow under extreme heat flux. Innovative enhancement devices were tested to raise the critical heat flux threshold, expanding the safe operating range of coolant fluids and lowering burnout risk. This breakthrough improves efficiency and marks a major step toward the commercialisation of fusion energy.

Outcome: Expanded safe operating range for fusion coolants, reducing burnout risk.

Featured case studies

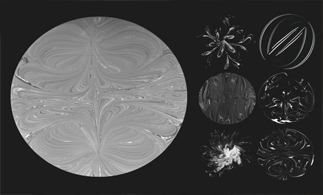

Quantifying Mixing with Planar Laser-Induced Fluorescence (PLIF)

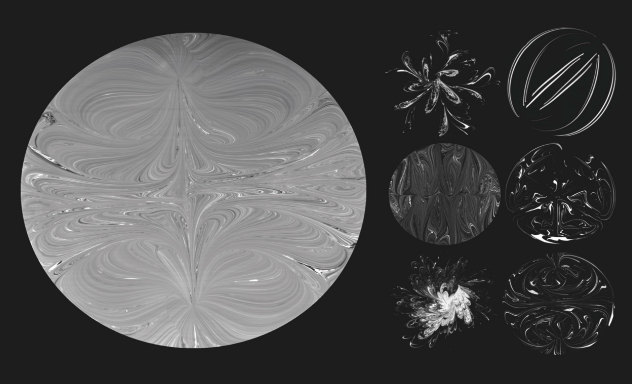

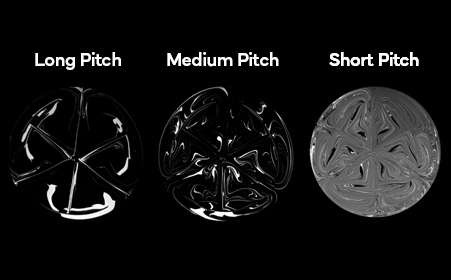

Mixing is central to many chemical processes, especially when handling viscous fluids. To assess the mixing performance of static in-line devices, we developed a facility capable of applying the PLIF technique in continuous operation at very low Reynolds numbers (Re < 30). The system enables fluorescent dye injection at either the tube wall or within the bulk flow, while image analysis, temperature, and pressure measurements were used to characterise a range of mixing devices.

New facility enables detailed mixing analysis at ultra-low Reynolds numbers.

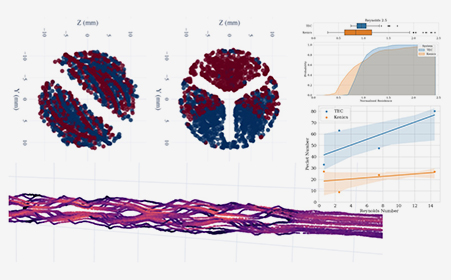

Investigating Viscous Flow with Positron Emission Particle Tracking PEPT

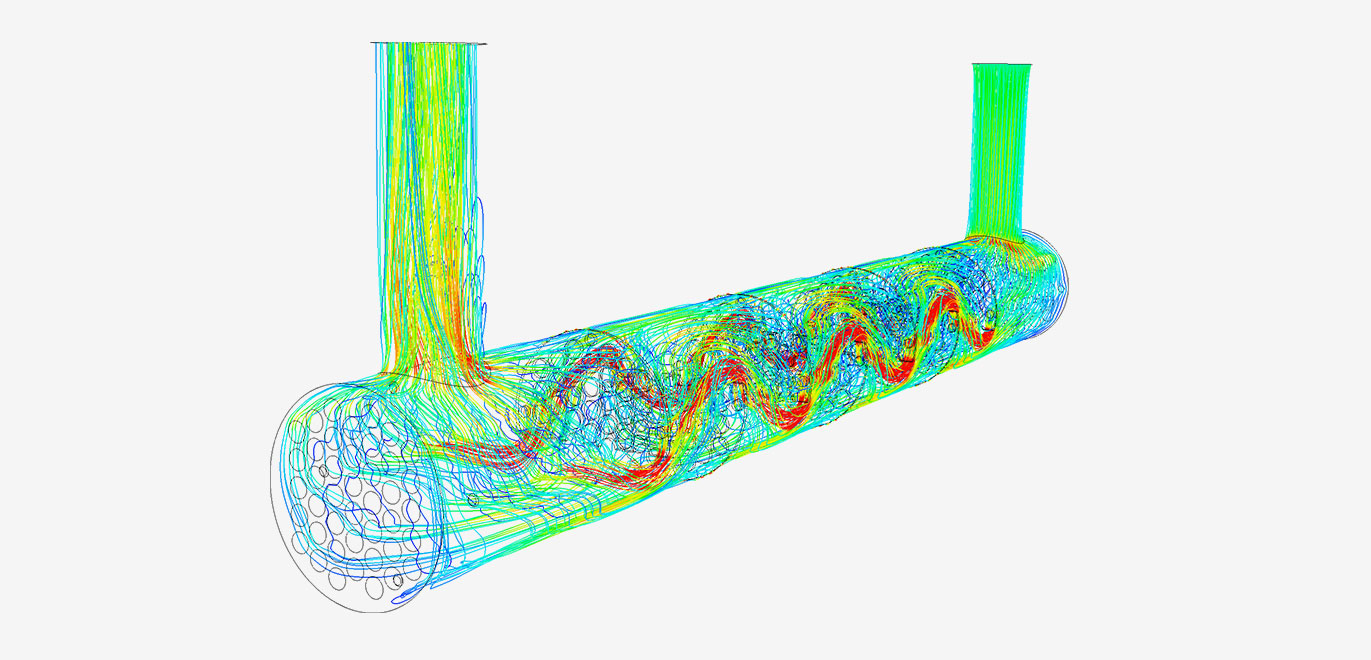

In collaboration with the University of Birmingham, we used the PEPT technique to study how insert geometries influence viscous flows. This non-invasive method enabled high-resolution 3D imaging of flow with excellent spatial and temporal accuracy. Novel Lagrangian approaches were developed to assess dispersion and calculate mixing indices, while complementary computational fluid dynamics (CFD) simulations validated the results and supported the exploration of new geometries.

Outcome: Combined PEPT and CFD deliver powerful insights into viscous flow design.

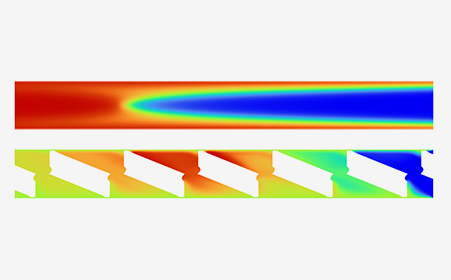

Computational fluid dynamics (CFD) with reaction kinetics and heat transfer

Accurately modelling in-tube chemical reactions requires methods that capture both flow dynamics and the influence of heat transfer on reaction kinetics. Working with a pharmaceutical partner on a thermally sensitive product, we developed a model to predict yields of the desired compound while accounting for unwanted by-products from a secondary runaway reaction. The results highlighted the critical role of residence time distribution and thermal stability in maintaining safe operating temperatures and preventing equipment damage.

Outcome: Advanced modelling reduces risk of runaway reactions and equipment damage.

An investment of Calgavin

Centre for Flow Processing is the Research and Development body of CALGAVIN Ltd. CALGAVIN is a British engineering company who specialises in improving the performance of tubular industrial heatexchangers and reactors saving operating and capital costs for our clients. The CFP helps the company in maintaining links with research establishments and helps apply key findings to engineering problems in the field of which CALGAVIN has access to. To know more about CALGAVIN’s engineering services and products please click below

visit calgavin.com